Thermal analysis of materials

Thermal analysis methods for studying temperature resistance, chemical stability and deformation.

Investigating the thermal behaviour of materials

Main methods of thermal analysis

DMA (Dynamic Mechanical Analysis), DSC (Differential Scanning Calorimetry), TGA (Thermogravimetric Analysis) and CTE (Coefficient of Thermal Expansion) methods are used to measure the physical and chemical properties of materials as a function of temperature, time or load frequency.

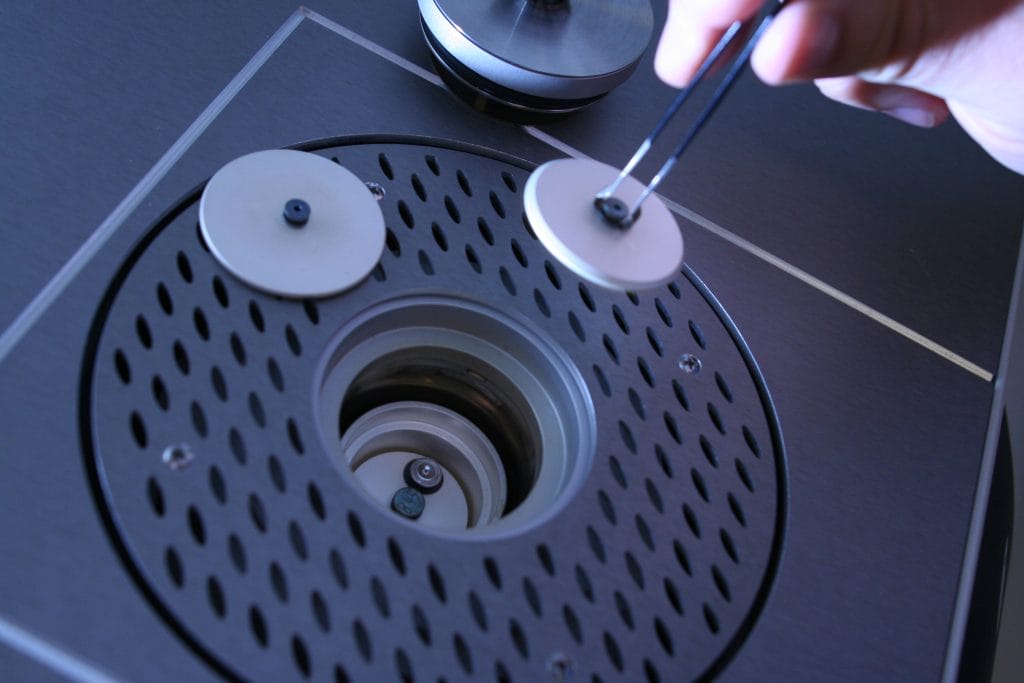

The DMA/DMTA method can be used to measure the viscoelastic properties of materials, such as stiffness and damping properties as a function of temperature and frequency. The method is suitable for determining the dependence of transition and operating temperatures, hardening reactions and mechanical properties.

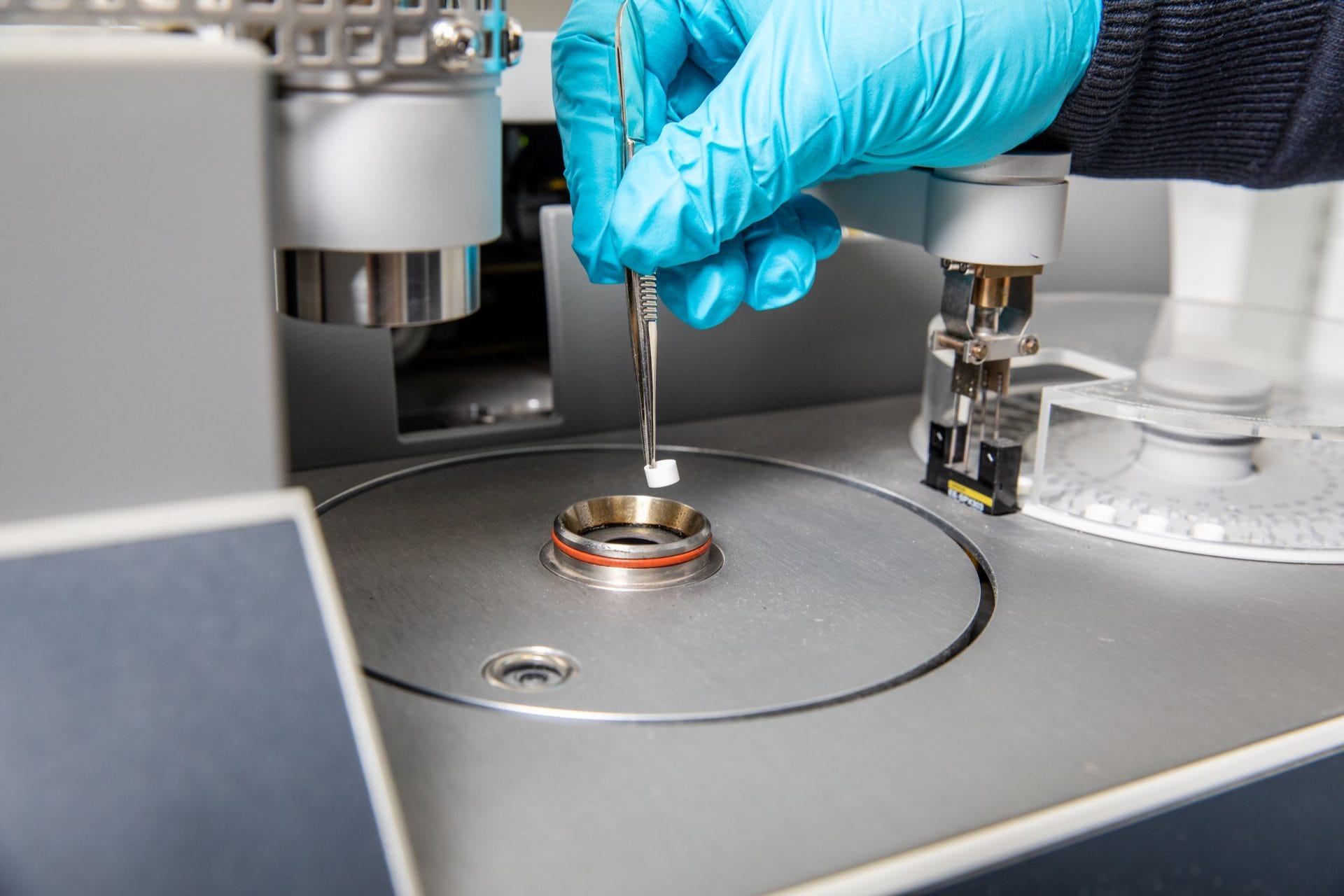

The DSC method is used to study the thermal properties of materials by means of enthalpy changes when the sample is subjected to controlled temperature changes. DSC can be used, for example, to determine melting and crystallization points and hardening reactions.

The TGA method measures the mass changes of materials as a function of temperature, which gives information about the material’s decomposition, heat resistance, evaporation or chemical reactions at different temperatures.

To determine the coefficient of thermal expansion (CTE) of materials, we use a strain gauge measurement in a controlled temperature range (-40…180 °C).

The most common test equipment used for thermal analysis of materials:

- NETZSCH DMA 242 E Dynamic Mechanical Analyzer (DMA)

- -170…600 °C, air atmosphere

- NETZSCH DSC 204 F1 Phoenix Differential Scanning Calorimeter(DSC)

- -85…700 °C, nitrogen, oxygen and carbon dioxide atmospheres

- NETZSCH TG 209 F1 Thermogravimetric Analyzer (TGA)

- 20…1000 °C, nitrogen, oxygen and carbon dioxide atmospheres.

Most common standards used in various thermal analyses:

- DMA: ASTM D4065, ASTM E1640, ISO 6721, ISO 6721, ASTM E1640

- DSC: ASTM E967, ASTM E968, ASTM E793, ISO 11357, ISO 11357

- TGA: ASTM E1131, ASTM E1582, ASTM D3850, ISO 11358

Our skilled experts

Mechanical testing of materials and structures

Condition testing of materials

Structural, compositional and elemental analysis of materials

Thermal analysis of materials

Surface analysis of materials

On-site testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Structural, compositional and elemental analysis of materials

Surface analysis of materials

On-site testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Wood modification

Fire testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Wood modification

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Structural, compositional and elemental analysis of materials

Thermal analysis of materials

Surface analyses of materials

Wood modification

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Thermal analysis of materials

On-site testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

On-site testing

Wood modification

Prototyping and testing of products and materials

Modification of test rigs

Mechanical testing of materials and structures

Condition testing of materials

Surface analysis of materials

Wood modification

Fire testing

Prototyping and testing of products and materials