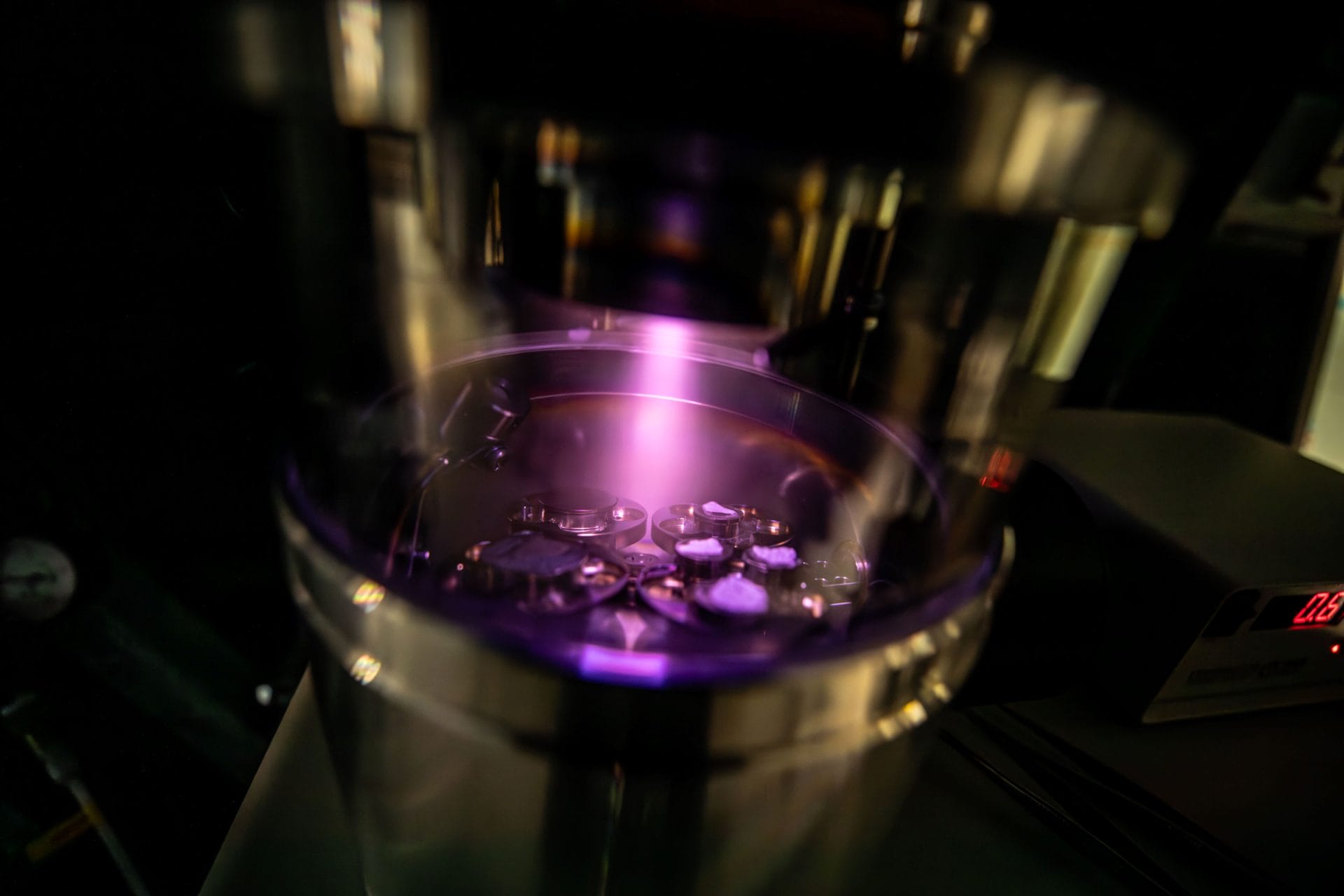

Surface analyses of materials

Surface analyses are used to investigate the surface structure, chemical composition, mechanical properties, morphology and possible impurities or defects of materials.

Our equipment and expertise provide detailed information on the surface properties of materials

Versatile surface analyses

For surface imaging we use microscopy methods, see page Structural, compositional and elemental analysis of materials.

We carry out hardness measurements on metals using standard Brinell, Vickers, Rockwell C and Barcol methods. We also have Brinell hardness measuring equipment for measuring the hardness of wood and polymer materials. We use the micro-Vickers method to determine the hardness of coatings or surface treatments.

To test the adhesion of coatings, we use an adhesion tester with a tensile strength range of 0….25 MPa. To test the adhesion of coatings, we use an adhesion tester with a tensile strength range of 0….25 MPa.

For surface colour and gloss measurements, we use spectrophotometers.

We use a contact angle meter to measure the contact angle between the droplet/liquid surface and the substrate to calculate the surface energy.

We determine the surface topography by 2D- or 3D profilometer measurements, which measure the roughness and waviness parameters of the surface under investigation.

We test the durability of materials and coatings using standardised Taber or Norman tests to simulate the service conditions of the material.

The most common test equipment used by Mikpolis for surface analysis of materials:

- Innovatest 423 A micro-vickers hardness measuring equipment

- Ernst AT 1800 T -hardness measuring equipment for metals

- Brinell -hardness measuring equipment

- Barcol-hardness tester

- AFFRI DRM 250 -hardness measuring equipment for wood and polymer materials

- PosiTest AT-A Automatic –adhesion tester with 20 mm/50 mm traction platform

- KonicaMinolta CM-26dG –spectrophotometer

- Krüss DSA 100 –contact angle meter

- Veeco Dektak 6M –stylus profilometer

- FRT Microprof –3D optical profilometer

- Taber Abraser 5131 -surface wear tester

- Norman Abraser –surface wear tester.

The more common standards we use for testing surface analyses:

- Vickers: ASTM E384, ISO 6507, JIS Z 2244

- Rockwell: ASTM E18, ISO 6508, JIS Z 2245

- Brinell: ASTM E10, ISO 6506, JIS Z 2243

- Janka: ASTM D1037-12

- Pull off: ISO 4624

- Colour values: ASTM E308

- Surface gloss: ASTM D2457, ASTM D523.

Our skilled experts

Mechanical testing of materials and structures

Condition testing of materials

Structural, compositional and elemental analysis of materials

Thermal analysis of materials

Surface analysis of materials

On-site testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Structural, compositional and elemental analysis of materials

Surface analysis of materials

On-site testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Wood modification

Fire testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Wood modification

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Structural, compositional and elemental analysis of materials

Thermal analysis of materials

Surface analyses of materials

Wood modification

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

Thermal analysis of materials

On-site testing

Prototyping and testing of products and materials

Mechanical testing of materials and structures

Condition testing of materials

On-site testing

Wood modification

Prototyping and testing of products and materials

Modification of test rigs

Mechanical testing of materials and structures

Condition testing of materials

Surface analysis of materials

Wood modification

Fire testing

Prototyping and testing of products and materials