Material crushing and micronization

BioSampo crushing methods

In BioSampo we have several methods suitable for processing materials. Current equipment is focused on the recycling of aggregates into concrete mixes by crushing or micronization when cement is substituted. The jaw crusher, roller crusher and ball mill are suitable for making micrometer-size powders. In the field of wet grinding, we have a cone crusher for soft and fibrous materials. The cutting mill is suitable for soft materials such as fabrics and biochar. We can screen powders into different fractions.

In our analytical laboratory section you will find a particle size analyzer that allows us to determine the size distribution of the grinding result.

Jaw crusher Retsch BB 250

A crusher suitable for hard materials and large pieces (e.g. bricks). The result is a wide range of sizes (from fine dust to a few centimeters), similar to gravel.

The desired size distribution can be achieved by screening or further processing, for example, in a ball mill. After screening, the material can be used as a substitute for aggregate.

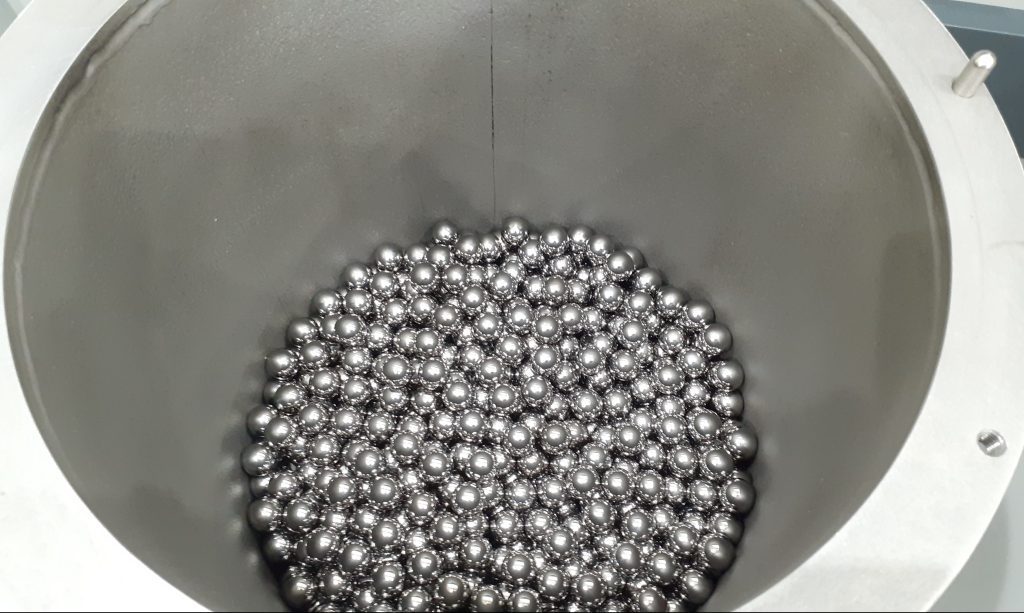

Ball mill Retsch TM 300

The ball mill is suitable for grinding dry and hard materials up to a mean volumetric size distribution of approximately 15 micrometers. It is equipped with steel tank and grinding balls. The surfaces are not resistant to corrosive substances or moisture.

The grinding sample volume is between 6 and 10 litres.

Ball mill Retsch MM500 Nano

The ball mill is suitable for grinding most solid materials up to a mean volumetric size distribution of less than 10 micrometers. It is equipped with steel receptables and grinding balls.

The grinding sample volume is 50 + 50 millilitres.

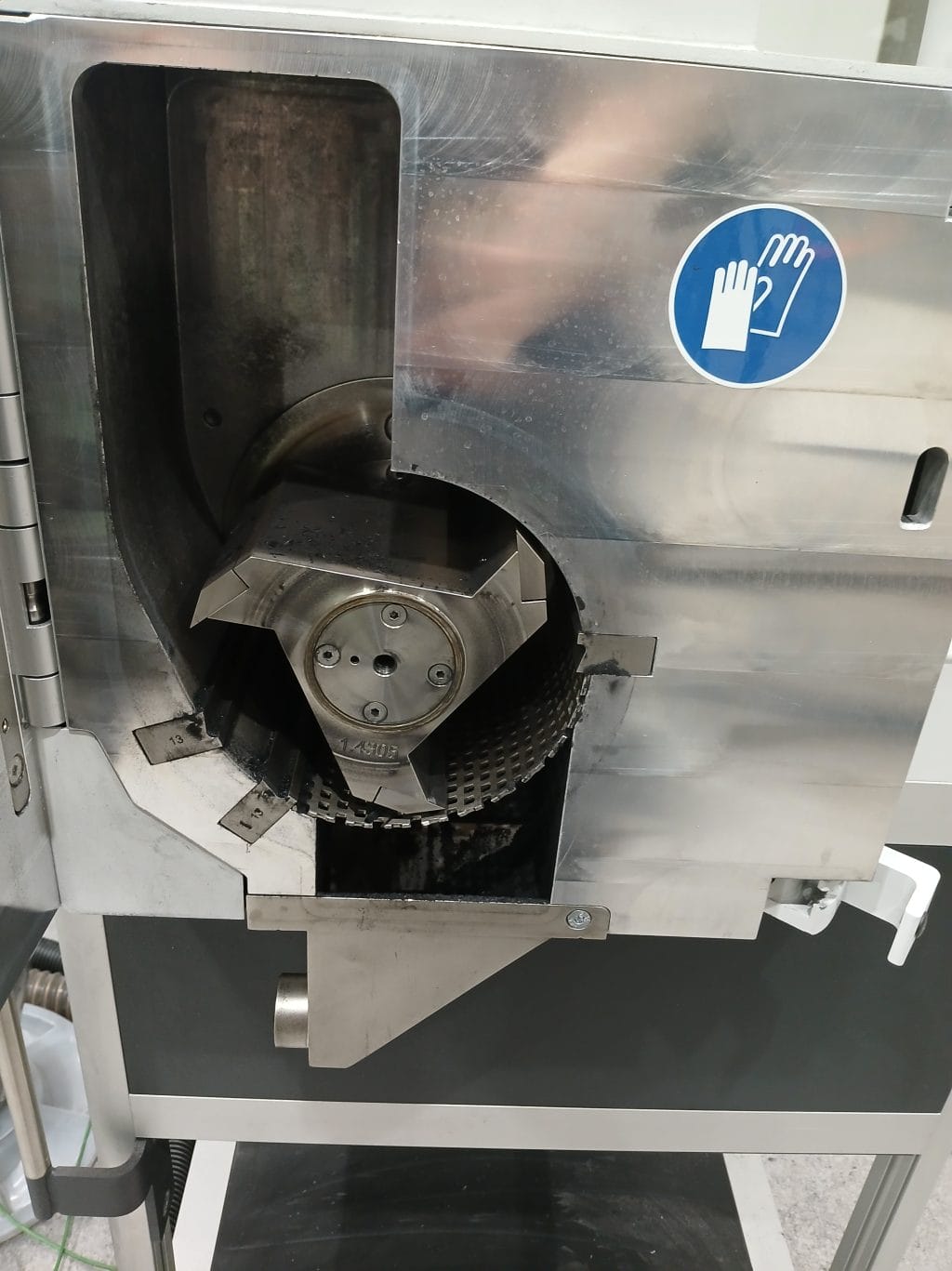

Cutting mill Retsch SM 300

A technique for shredding soft materials. Fabrics and woody materials are reduced to millimeter size. The sample can be processed at a rate of approximately tens of liters per hour.

Roll crusher

The machine has two rollers placed close to each other, which crush the material into a powder.

The machine is designed to crush hard materials. The machine produces a wide range of powder sizes, from a few microns to a few millimeters.

The sample can be processed at a rate of approximately tens of liters per hour.

Cone crusher KID 300K

The equipment is a wet grinder and the material must have a minimum moisture content of 50-70%. If necessary, the material is wetted during the grinding process.

The feed size limit is 25 × 15 × 5 mm, with wet grinding achieving a particle size of less than 2 mm.

For soft biomaterial, a volume median size distribution of 80 microns has been achieved.

The wet pulp can be ground at a rate of approximately 200 kg per day.

Sieving machine Retsch AS200 Control

Non-centrally vibrating sieving machine. Suitable for sieving hundreds of grams at a time. The machine has parts for wet and dry screening.

The sieves are 200X50 mm:

20 μm

45 μm

63 μm

90 μm

125 μm

180 μm

250 μm

500 μm

1 mm

2 mm

4 mm

8 mm

8 sieves can be used simultaneously.

Sieving machine Kapotek vibratory separator

Tens of kilograms of dry powder can be screened in continuous operation with the vibratory sieve shaker.

The sieves have 800 mm diameter:

0,5 mm

1 mm

2 mm

The screens are used in the mentioned configuration for the ideal operation of the equipment.