Response Demonstration Areas for Spills of Renewable and Bio-based Liquids

Project aims to improve preparedness for spills of new generation fuels.

Oil spill response testing for alternative fuels and liquids

Preparing for spills of new fuels and liquids

The field of oil and chemical spill response is facing a new challenge: the introduction of recycled raw materials and alternatives to replace fossil fuels, which also requires an

adaptation of the response capability.

Effective response measures necessitate knowledge of the hazardous properties of the substances, their spill behaviour and recoverability. To discover this information, South-Eastern Finland University of Applied Sciences (Xamk) launched this development project to carry out practical response tests.

New testing and training facilities

The tests were conducted at Xamk’s Oil Spill Response Test Basin in Kotka, Finland. The tests required the establishment of new research and testing environments.

Why was the project needed?

Substitutes for fossil fuels are becoming more common. This change will also have a reflection effect on environmental incidents and spill response preparedness: new substances will require new response competence. The project addressed this need by conducting practical tests at the Xamk Oil spill response test basin to determine the response potential of the new generation of fuels and their raw materials, and by disseminating the acquired knowledge through demonstrations to response operators.

The tests required the implementation of new research and testing structures. Three new platforms were built:

- a solid slope ground and flowing water research unit,

- soil testing columns and

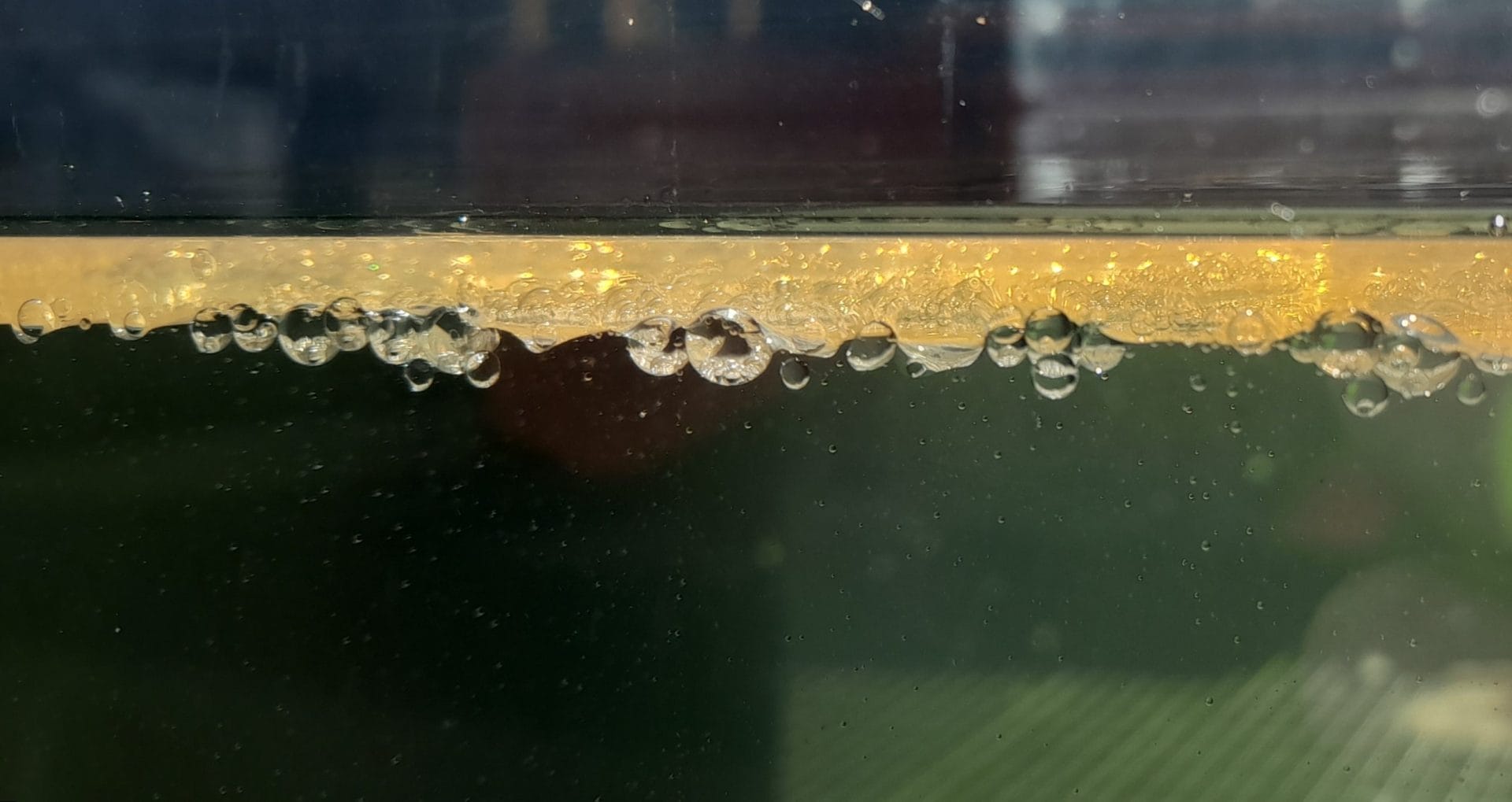

- a water aquarium for the demonstration and study of the spill behaviour of substances.

The structures complement the oil spill response testing and innovation platform and increase potential for methodological and product development.

How the spill behaviour and response tests were carried out?

The tests consisted of demonstrations of spill behaviour in open water, ice conditions and soil, and a recovery test. A total of 27 demonstrations and tests were carried out on five novel products: technical animal fat, Neste MY Renewable Fuel Oil, liquefied waste plastic, crude tar oil and UPM BioVerno diesel. Fossil light fuel oil, marine diesel oil and hydraulic oil were used as reference products, with a partial use of heavy fuel oil and crude oil.

The testing proceeded in stages. First, the spill behaviour of the substances in the water was investigated. The aim was to observe whether the substance floats or sinks, how it spreads on the water surface and how it mixes with the water.

The renewable fuels tested did not differ significantly from their fossil counterparts in terms of spill behaviour. In contrast, the raw materials of the products as well as the liquefied waste plastic behaved differently from conventional oils.

What the results looked like?

The results of the spill behaviour test were used to evaluate the applicable response and recovery method. The renewable fuels, recycled liquids and raw materials tested were divided into mechanically removable solids and recoverable liquid solids.

Skimmer recovery tests were carried out to verify the feasibility of the latter. It was found that some of the new generation fuels have a higher tendency to form emulsions, leading to an increase in the total liquid volume and the need for intermediate storage capacity.

It was found that the choice of skimmer type has a greater impact on the outcome than whether the fuel is of fossil or renewable origin: significant differences in oil recovery efficiency were found between the different types of oil recovery skimmers.

When evaluating the result, it has to be taken into account that the tests were carried out only for a limited number of substances and, in addition, products unsuitable for skimmer recovery were excluded from the tests on the basis of the spill behaviour. Therefore, the results should not be applied to products made from renewable, bio-based or recycled raw materials in general. Instead, the tests provided substance-specific information. In particular, the tests showed the importance of determining the most appropriate recovery method for each product. Testing should therefore be extended to a wider range of new generation fuels.

The permeability and penetration of new-form fuels were determined in three soil types. The tested novel substances were found to have a faster permeability than the fossil ones, but there was little difference in the degree of retention of the substances in the different soil types.

The project also aimed to test oil absorption products made from renewable or recyclable materials. The tests compared absorption products made from recycled or recyclable materials with synthetic ones. A more general description was also given of how spill response measures can take into account sustainable development principles and minimise the amount of oily waste generated.

The project’s testing activities were the first of their kind and provided completely new information not previously available to competent authorities, refineries or manufacturers of response equipment. The results have a significant impact on the response competency of the target group, and the use of this information in incidents involving novel substances can minimise harm to people and the environment. The increase in knowledge was reflected in both verbal and written feedback: participants’ knowledge of how to respond to new substances increased significantly.

New research and testing structures will enhance the capability of the oil spill response testing facility to generate new knowledge, deepen specialist expertise in environmental pollution and innovate technological response solutions. The unique RDI environment will strengthen the region’s expertise and also provide a vehicle for international partnerships, as the decarbonisation of fossil fuels is a global objective. The results of projects that strengthen RDI activities support the Kymenlaakso smart specialization strategy (RIS3), Kymenlaakso Regional Strategy and the EU Strategy for the Baltic Sea Region. The results of the project contribute to ERF horizontal principles of sustainable development by reducing the environmental impacts of the spills of new generation fuels.

Publications

Responding to Spills of Marine Distillate Fuels

A Hair-Raising Novelty for Onshore Oil Recovery?

Contact

Facts

Response Demonstration Areas for Spills of Renewable and Bio-based Liquids

Info

Budget

Project partners